Genesee Generating Station Environmental Analysis

| ✅ Paper Type: Free Essay | ✅ Subject: Environment |

| ✅ Wordcount: 1242 words | ✅ Published: 23 Sep 2019 |

GENESEE GENERATING STATION 1&2

AIR POLLUTION LAB

INTRODUCTION

The Genesee Generating Station has a 5 units (1, 2, 3 4, 5) units that generates power at varying capacities. These three units of Genesee are providing 1,376MW of base load power for Alberta’s electricity grid.Genesse unit 1(G1) was commissioned in May 1994 and its gross capacity of 430MW.Whereas (G2) was the first unit to be completed and was commissioned in October 1989.and its cross capacity is 430 megawatts. Both subcritical units consists of a pulverised coal-fired pressure, boiler, steam turbine and electrical Generator. The next annual production of both G1 and G2 is approximately 3,297 gigawatts /hour (GWH) and both requires approximately 3.4 million tonnes of coal annually (2015).On the other hand Genesee unit (G3) Was the first coal fired unit in Canada to use supercritical boiler technology.G3 requires approximately 1.9 million tonnes of coal annually (2015), and net annual production is approximately 3955 GW. It was commissioned in March 2005, G3 is an equal joint venture partnership between capital power and Trans Alta.

In case of units 4 and 5, it is a combined cycle natural gas-fired generation facility. Its capacity will be upto1, 050MW.The expected life of a natural gas fired facility is generally 35 years.

Operating Features

Genesee generating power station is one of largest power station in Canada which provide the power to the whole Alberta province. With the passage of the time and due to its serious effects the minor improvements were done. But the basic functioning remains the same.

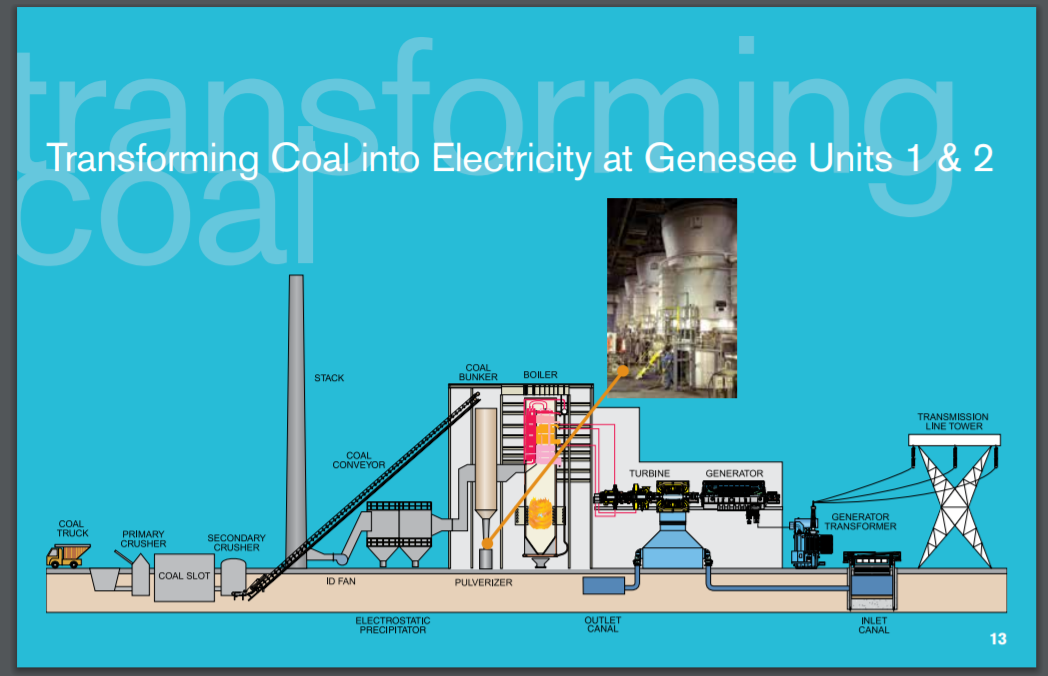

Its working generally consists of

- A boiler

- Steam turbine

- Electrical generator

- Condenser

- Cool handling system

Before the working of the boiler starts, there are few more steps to initiate the process like-

- Crushing the coal– with the help of the conveyor the coal is crushed to five inch pieces then again it crushed to 2 inches .then, coal is conveyed outside to a live storage pile.

- Moving the coal into the plant-by the conveyor the crushed coal is delivered to the generating plant and stored in 16 five storey high bunkers each with a with a six hour storage capacity.

- Pulverizing of the coal– From the bunkers the coal is fed into mills which pulverize the coal into fine powder about the same consistency as flour, where it is mixed with hot air and blown into the boiler of the generating plant.

Process starts:

- BOILER: In this mainly the blowing of the coal into the furnance.Hot air from the nearby fans blow the powder like coal into gigantic 66 meters high furnace or boiler. There burners instantly ignite the coal and air mixture to achieve combustion and create the maximum amount of heat possible. Temperature inside the bowler may reach 1300c. Intense heat from the burning coal turns the purified water inside the boiler tubes into steam, just like water in a kettle. G3 supercritical boiler technology .have higher temperatures and steam pressures together with high efficiency steam turbine create a more efficient process for converting thermal energy into electricity.it produces stem at 26 Megapascals and 50% higher than G1 AND G2.

- STEAM TURBINE: The high pressure steam from the boiler passes through pipes into the turbine. When the steam hits turbine blades, it causes the spin rapidly, at approximately 3,6000rpm.A single shaft connects the turbine an electrical generator. The rotating shaft turns electromagnets within a series of wire coils, creating electric current producing electricity (Generator).

3.CONDENSOR: A Condenser for every unit charges over turbine debilitate steam once more into water so it can be come back to the evaporated for reuse in the steam producing process .In the shut cycle a similar water is utilized over and over. After its outing through the condensers, this cooling water is pumped thorough the gigantic cooling towers.

4. COOLING POND: There is one artificial pond covering the approximately 735 hectares area.it contains 34 million cubic meters (m3) of water. It can provide the cool water for up to four 400MW units. The water level in pond is maintained by pumping water from North Saskatchewan River and supplemental with local run-on.

5. ASH HANDLING: It is a valuable by product are created as a result of burning coal. Coal from this mine contains between 13-20% ashes. Approximately 99.5%of the ash is recovered and put into permanent storage or sold for industrial uses. It is further used in cement (instead of kilning limestone’s), coal –fired power plants reduce the greenhouse gas emission of the combined industries.

ENVIRONMENTAL PERFORMANCE

The environmental performances of different units have different results like

(In unit G1, 2, 3) is –

(I) CO2 Emission– G1and G2 produces more carbon dioxide in the air that is directly responsible for greenhouse effect but G3 produces 8-10%lower than existing G1 and G2 and 18%lower than average Alberta coal generation.

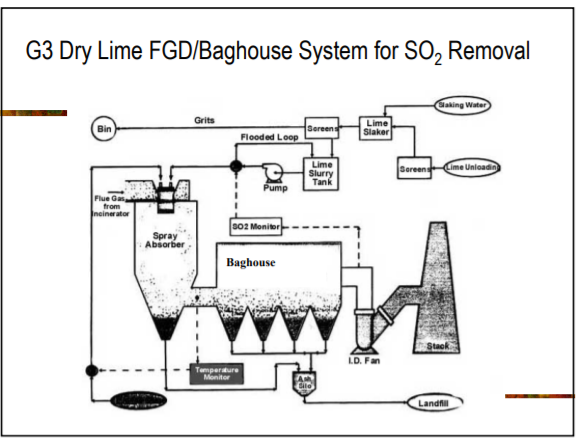

(II) SO2 emission: SO2 emission from G3 is 57%below Alberta standards. FGD unit captures up to 77%of so2 emission.it meets US EPA emission standards.

(III) NOx emission: In G3 there is 20% reduction of NOx. Which meets Alberta standards. Particulate matter emissions :> 99.8$capture efficiency.

In case of G4 and G5 there is improvement in environmental emission than G1, G2, G3 and this improvement is just because of natural gas-fired turbine technology (CCGT).

- This advanced CCGT technology ensures greater efficiency and will help Alberta continue to reduce greenhouse such as nitrogen oxides (NOx). It mainly reduces the emission of NOx. Moreover, there is no additional diversion of water from the North Saskatchewan River.

- Greenhouse gases: GGS Units 1-3 are subject to the specified Gas Emitters Regulations (SGER) under the climate change and emissions management act (Alberta). SGER requires companies that emit more than 100,000 metric tonnes of carbon dioxide equivalent (co2) to reduce the emission intensity of facility by 2% per year to a maximum of 12%.(1)

- AMBIENT AIR QUALITY: The existing GGS facility partners in the Wabamun—Genesee Area Biomonitoring Program which studies the environmental impacts of power generation. Within this program, ambient air (SO2, NO, NO2, NOx, PM2.5) is monitored at the Genesee air monitoring station and the results are reported to ESRD.(1)

Results of the air emission modelling:

The maximum predicted concentrations for NO2, SO2, PM2.5, CO and NH3 associated with emissions from GGS Units 4 & 5 for all relevant averaging periods are predicted to be much lower than the corresponding Alberta Ambient Air Quality Objectives (AAAQOs). Model predictions indicate little difference between Base Case (existing activities) and Application Case (existing activities plus GGS Units 4 & 5) results, with maximum predicted concentrations of key substances of interest increasing less than 3%. This indicates that GGS Units 4 & 5 is not expected to materially increase maximum concentrations of these substances within the study area

REFERENCES

- G4 G5.Open House Board.(2014).Retrieved from https://www.capitalpower.com/generationportfolio/CA/Genesee/G4G5Docs/2014%20April%20G4%20G5%20Open%20House%20Boards.pdf

- Genesee Tour Brochure. (2016). Capital Power Corporation’s Genesee Generating Station. Pdf. Retrieved fromhttps://www.capitalpower.com/generationportfolio/CA/Genesee/G3MoreInfo/Genesee%20Tour%20Brochure%20(2016).pdf

- Genesee project information brochure. (2013).A New Power Generation Opportunity for Alberta. Genesee Generating Station units 4 and 5.Retrieved from https://www.enmax.com/GenerationAndWiresSite/Documents/Genesee-4-5-Project-Information-Brochure.pdf

- Dr.kindzierski w. (2007).EPCOR Genesee station phase3 (slides).CIV E 240 Technical Communications. Retrieved from http://www.energyquest4nanticoke.ca/gen3c.pdf

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allDMCA / Removal Request

If you are the original writer of this essay and no longer wish to have your work published on UKEssays.com then please click the following link to email our support team:

Request essay removal